sick

Being sick is a very unproductive way to go through a week.

Here I will cover the build process in which I try to turn a pile of steel and an old junker into a locost super seven based on the lotus super 7 cars.

Being sick is a very unproductive way to go through a week.

Posted by

Chris

on

12/20/2006

0

comments

![]()

Well, I have the wiring harness out as well as the steering column. I hope to get the steering rack and brakes out this weekend.

I picked up a pipe bender at HF. I am going to try and bend my last rear tubes and try and finish the frame before the end of the year.

Posted by

Chris

on

12/13/2006

1 comments

![]()

I have been plinking away at the harness. I have everything unhooked but the computer, which is partially buried behind the heater assembly.

This weekend I should have it out and I should start on the gas tank and the steering rack.

Soon ol' ugly'll be gone. <Sniff>

Posted by

Chris

on

12/07/2006

0

comments

![]()

This weekend I made some small progress.

Posted by

Chris

on

12/04/2006

0

comments

![]()

The engine and transmission are now in 2 separate pieces. It appears the clutch is non-hydraulic. That is a nice thing and will make the pedal box easier to deal with. The clutch plate still had life on it, but I think the speedo cable is broken. I imagine it's not supposed to be in 3 pieces. Now to strip the rest of the car....

-C

Posted by

Chris

on

11/29/2006

0

comments

![]()

I took the bra off the car....eeeeewww. Leprosy of the paint.

Here's the car right before removal:

Here's the result.

...one heavy lump. Plus if you look closely you can see the valdez sized spill where the tranny dumped the fluid.

Posted by

Chris

on

11/27/2006

0

comments

![]()

I have outed my engine. Thanks to lots of help from Bob (guy on left) and the equipment loan from Dean the Lima Lump is on the garage floor. Dang it is heavy. I'll post pics tonight.

Posted by

Chris

on

11/27/2006

0

comments

![]()

http://www.youtube.com/watch?v=h9UVV0XuiDk

Not positive what version of a 7 car it is, but it's cool. This was one of the things that got me interested in this project.

Posted by

Chris

on

11/16/2006

0

comments

![]()

I would say the most difficult thing about this build has been finding the free time to do it. 2nd would be the compound angles with a cheap harbor freight cut-off saw.

If I build another one of these frames in the future, and I might, I'd liker to have a dedicated shop, because jockeying the motorcycle and M out of the garage every time I want to work gets a little old. In that shop I would place a metal band saw and a plasma cutter along with a large bench grinder.

All in all, I am happy with the amount I have done in little over a month. I will have to begin donor surgery soon. That will also cause a cramping of space as I extract parts and have to make room for them.

Posted by

Chris

on

11/08/2006

0

comments

![]()

Got some stuff done yesterday. Not as much as I wanted to. I spent a while trying to figure out how to do the bends. No luck yet. I'm gonna build the bender myself, I think. I'll post a pic of it if it is successful.

Much of this week will be un-productive. I am out 2 nights for a biz trip.

Posted by

Chris

on

11/07/2006

0

comments

![]()

Stopping and looking back. It's been a month since I started fabrication on this thing. I have gotten a lot better at welding, but I would say that my biggest issue is getting the pieces cut right. My Harbor Freight Chop saw is not a precision instrument and I have to cut long and grind to fit. I also need to figure out my tube bending. I may get a bender this weekend and this will be a moot point, but if not I think I'll be back at HF buying something.

I still have the donor dis-assembly ahead. Some of that is going to be fun, but I don't expect it to be smooth. I can't remember the last mustang I disassembled.

Overall I am glad I started this. It keeps me busy and it is a constant source of fascination. I find new and cool sites all the time that are related to Locosts or car fabrication in general. I'm going to spend a few minutes and update the site. I have a lot of bookmarks that need to be organized.

I won't be getting much done this weekend since I need to go to Portland for a family affair. I need to get actual pictures of the frame up here soon.

-Chris

Posted by

Chris

on

11/03/2006

0

comments

![]()

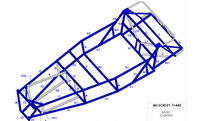

I've changed the base image to add the tranny tunnel tube for the progress meter. I am still quite a ways in to it and have about 15 more tubes to go.

Posted by

Chris

on

11/02/2006

0

comments

![]()

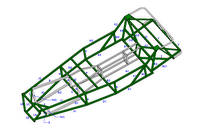

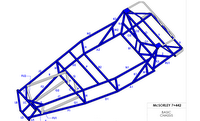

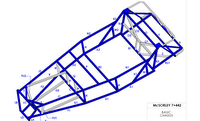

See if you can find the differences. If I could round up a bender I'll be in great shape. I am debating adding all the Australian mods for frame stiffness. I also need to figure out what to do about front uprights.

Posted by

Chris

on

11/02/2006

0

comments

![]()

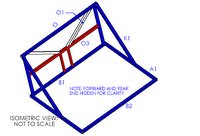

Here's the latest.

I got 3 whole tubes in. The next cuts are another set of compound angle. Those take forever.

Below is the 3 new tubes in Red:

Posted by

Chris

on

10/31/2006

0

comments

![]()

Well the latest progress pic doesn't show much more than the last one. We had house guests all weekend and I really only had a bit of time to work on the car. I spent a good chunk of that time getting more steel.

Note. Make sure if you decide to have your steel cut into car compatible chunks that you get them cut to the longest piece you will be needing (top tube). Last week I bought all my round tube and instead of thinking, I had them cut them into 5 foot pieces. One of the pieces needed to be ~70 inches so I was looking at trying to join 2 small pieces into one long one or just ponying up 7 bucks for the length I needed.

Oh well, If i expected to get it right every time I'd be doing an easier project.

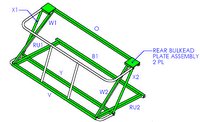

So all I got done are the:

rear bulkhead assembly plates and the supports (x1,x2,w1,w2)

I left all the bends for later. I may be borrowing a bender from my Dad this weekend. If so it will make that a lot easier. Otherwise I'll build my own.

Next weekend I'll be out of town, so Evenings is all I've got this week.

Posted by

Chris

on

10/30/2006

1 comments

![]()

inspiration

and

this

Was informed to warn users that the above links go to Youtube.

Posted by

Chris

on

10/27/2006

1 comments

![]()

So I am now thinking about what the car will be named when it is finished. Luckily I have a lot of time to mull this over. However I am going to open it up to suggestions. What about it? Bob, Dean, Todd?

Here's my first thought

Nigel

or Billingsworth

or Some title from either Molly Hatchet or Black Sabbath

Posted by

Chris

on

10/23/2006

1 comments

![]()

I got more of the frame constructed, but I forgot to pull the pictures off the camera. I'll add them tonight. Got the cross tubes tacked in and started to assemble the section tha sits behind the seats.

in this picture the stuff I got done is red:

In this version, the blue is done and the red is what I did this weekend.

Posted by

Chris

on

10/23/2006

1 comments

![]()

Business travel and guests have made this an unproductive week. I hope to get caught up on the weekend. Lots of welding and grinding to get done.

Posted by

Chris

on

10/20/2006

1 comments

![]()

OK here are the newest progress pics...

Another angle (note the worlds worst bench grinder in the background):

Posted by

Chris

on

10/16/2006

4

comments

![]()

Over the weekend I managed to get the frame into the 3rd dimension. Let me sat this. getting the Jigs set up is a lot of work. As is getting the longish bits to fit where they belong.

Posted by

Chris

on

10/16/2006

0

comments

![]()

I found a guy 20 minutes away who sells Locost body parts and fasteners. I'm going to try and check it out sometime.

Kinetic vehicles in Creswell, OR

Posted by

Chris

on

10/13/2006

0

comments

![]()

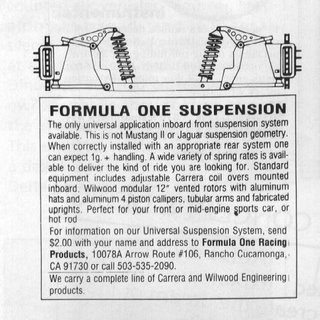

Saw a cool design for the front suspension.

Also this one seems interesting to me. But those A-arms are really far back.

Other than that I have done little but file down my welds from this weekend. I pl,an on working on this on Friday and Saturday this week so I should have some good progress to show by Monday.

Posted by

Chris

on

10/11/2006

0

comments

![]()

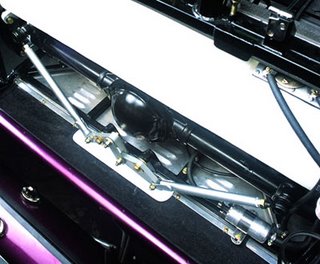

I got these cheap on Ebay. they are the right length for either front or rear. If I can find 1 more 99 r6 shock I should be set for the first suspension build.

Posted by

Chris

on

10/08/2006

0

comments

![]()

I started to weld the bottom rails yesterday. It went pretty well once I got it dialed in. I used a piece of ground wire and hooked it to the welder ground and the other piece in the weld to make sure that the weld would go smoothly.

Seemed to work great, however some of the welds are pretty messy. I'll have a bit of cleanup with the grinder to do.

Posted by

Chris

on

10/08/2006

0

comments

![]()

OK. Bottom rails are all ready to weld. I'll hit that this weekend. Tomorrow I have to go to Seattle for business. I'll use some scraps to make sure the welder settings are right for the tubes.

Also I won an auction for an R6 shock. I think I'll use these for the fronts. Now I have to find a second one.

Posted by

Chris

on

10/04/2006

0

comments

![]()

Yesterday I exchangd the 5/8 for 3/4. Schnitzer steel was cool about it. I spent last night laying out the bottom rtails and jigging them together ar the appropriate angles. It was slow, timeconsuming work but peaceful and somewhat relaxing. I guess I understand the people who build ships in a bottle a little better now.

Also, my buddy Dean has offered up his engine hoist and stand for me to use. That's going to be a big help.

Tonight I should do some more layout and maybe I can start tack welding this weekend.

Posted by

Chris

on

10/04/2006

0

comments

![]()

2 things happened last night of interest.

1. I realized I was using the +4 plans instead of the +442. The upshot of this was that I had some more cutting to do for the bottom rails.

2. I finally put a tape measure to my 3/4 stock and realized that it was 5/8 stock. Now I need to go back to the steel store and make a return. That should be fun. Luckily it isn't very much to return.

Posted by

Chris

on

10/03/2006

2

comments

![]()

Here is the wagon all loaded up. Not very heavy at all.

120 feet of 1x1 and 40 feet of 3/4 x 3/4...

Here is the bottom rails laid out. I need to clean all the ends up before tacking together. It is pretty cool to see some progress.

Posted by

Chris

on

10/01/2006

3

comments

![]()

Good news, the steel place is gonna cut them in half for me for free. No 20' sticks on top o' the car for this guy.

Posted by

Chris

on

9/28/2006

0

comments

![]()

Tomorrow I buy tubing. I think duct tape will be my friend for this task. I'll take a picture of it loaded on the car.

I've been spending a lot of time thinking about rear suspension. I think I may try to do a mumford link instead of a panhard rod.

It'll be more complicated but I've heard great things about them.

Posted by

Chris

on

9/28/2006

0

comments

![]()

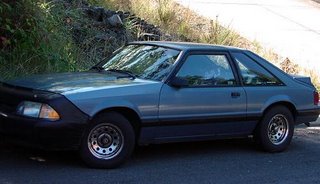

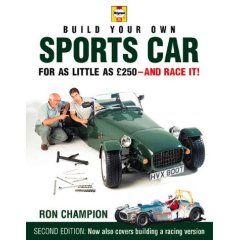

since I have nothing much to report today, I thought I'd post a picture I found. This is the general style od the finished project.

Posted by

Chris

on

9/27/2006

0

comments

![]()

Spending some time today to think about if I do + 4 or a 442 version of the car. +2 has extra engine compartment room. I'm leaning that way. The weight difference should be ~50 lbs all told.

Posted by

Chris

on

9/27/2006

0

comments

![]()

Time to start acquiring the metal. I plan on picking up the materials for my build table tomorrow and the steel on Friday. I'll have to cut down the pieces since it comes in 20 foot lengths and my garage is only 19.5 feet long. I'll be hauling it on the roof rack of my passat. That'll be funny looking.

Posted by

Chris

on

9/26/2006

3

comments

![]()

OK I got a donor. During a trip to Portland I found a good bargain donor. A 1988 Ford Mustang (4 cyl).

The car has 91,000 miles on it and it only has a few things wrong with it:

Posted by

Chris

on

9/24/2006

0

comments

![]()

No movement on the donor car front. Watching Craigslist and waiting.

Posted by

Chris

on

9/20/2006

0

comments

![]()

Looked at a donor celica this weekend. Guy didn't have title. Backed out at that point. Also the car wah hammered and had 350k on it I don't need to hurry here.

Posted by

Chris

on

9/18/2006

0

comments

![]()

OK. Off to portland to examine and hopefuly buy a donor Celica gt-s.

Posted by

Chris

on

9/15/2006

0

comments

![]()

This is an interesting suspension idea, I'd love to attempt it, but I think I will build a normal laout later and try this out after all runs. ... Could be a while at that

This is an interesting suspension idea, I'd love to attempt it, but I think I will build a normal laout later and try this out after all runs. ... Could be a while at that

Posted by

Chris

on

9/14/2006

0

comments

![]()

I've been getting lots of advice on what to use for a donor. Some a bit farther out of reach than others. I am now leaning to old celicas. I could build a de dion rear end with the IRS and have an interesting car.

This project is always in the back of my head, like a song you just can't stop singing. OCD?

Posted by

Chris

on

9/14/2006

0

comments

![]()

Well, the first major hurdle is cleared. My wife has given me the go ahead for the project. She even suggested I make a list of tools I may need to go forward to give out as gift ideas to people. All in all a positive development.

I've been researching cars a lot for the donor. I plan on using a Toyota or Suzuki donor which will allow me to mate a VW TDI engine into it when I can get a deal on one.

Posted by

Chris

on

9/12/2006

0

comments

![]()

OK.

Sign off from wife - Pending but positive so far

I priced the tubes, 120 for all the 1 x1 and al the .75 x .75 locally

Posted by

Chris

on

9/11/2006

0

comments

![]()

I think I'm going to build a McSorley 442 model. It is 4 inches longer and wider and has 2 inches more height, thus the 442.

My last steps before officially doing this are:

Posted by

Chris

on

9/11/2006

0

comments

![]()

After reading the car and driver article I ruled out one of my donor cars. I had considered a 320i or a 318i as a donor, but they are fairly lackluster hp wise, however a e36 318 might be a better candidate since it came with 134 hp, or 34% more power than the 80-86 BMW 4 banger. I also know I can pick up RX7s for cheap, however I'm not very experienced with the rotary as far as repairs are concerned, but I like the weight and output.

My list is looking like this so far:

Posted by

Chris

on

9/07/2006

0

comments

![]()

OK, got a tip. Thank you Sears. So I start to practice on a 1/8th in piece of stock and there goes the circuit breaker.

Hello Home Depot. I ended up wiring a dedicated 20 amp breaker and outlet into the panel to run the welder and my compressor off of and used some 12/2 gauge wire to connect them. While I was in there I also put a 20 amp breaker in for the garage circuit. By the end of this it was to late to play with the welder anymore.

Posted by

Chris

on

9/05/2006

0

comments

![]()

Need to get a new tip for the welder to use the flux core. It's a bigger diameter. I'll get a pic of it soon. My wife has the camera on a trip at the moment.

I did find an interesting site today: http://www.ecodeparts.com/ They sell euro diesel engines. they have a 1.4 tdi that gets 60+ mpg. If I could put that in this project with 500-1000 lbs of weight reduction over the car that gets the 60mpg I could get 75mpg+ and still be quick.

Posted by

Chris

on

9/04/2006

0

comments

![]()

I bought a welder last night. I found what seems to be a good deal on a Century (bought out by Lincoln in 2003) welder. Now to start practicing. Photos later.

Posted by

Chris

on

9/04/2006

0

comments

![]()

Someone sent me a link to this site:

Now I can start thinking about using Bio-power for this project.

Posted by

Chris

on

9/03/2006

0

comments

![]()

I've been reading up on welding. I realize that I will need to get better at it before I start the project. Lincoln has a great site wirth articles and FAQ's.

Posted by

Chris

on

9/01/2006

0

comments

![]()

Tools I will most likely need:

Posted by

Chris

on

8/31/2006

0

comments

![]()

OK first steps:

Surf the web for info and

buy the book

I will add links to good sites on the side bar as I find them.

Posted by

Chris

on

8/31/2006

0

comments

![]()

I am going to document my locost super 7 build here in hopes that:

a) I can actually complete the project

b) Someone else finds it useful.

-Chris

Posted by

Chris

on

8/30/2006

0

comments

![]()